In the logistics and shipping industry, the concept of DIM (Dimensional Weight) plays a crucial role in determining shipping costs. The DIM Divisor is an essential component of this calculation, affecting how much businesses pay to ship their goods. By understanding the DIM Divisor and its implications, businesses can better manage their shipping expenses and optimize their packaging strategies.

What is DIM? (Dimensional Weight)

Dimensional weight, commonly referred to as DIM weight, is a pricing technique used by shipping carriers to account for the space a package occupies relative to its actual weight. This method ensures that carriers do not lose revenue on large, lightweight packages that take up significant space. DIM weight is calculated by measuring the package dimensions, multiplying them, and dividing by the carrier’s DIM divisor. The higher value between the DIM weight and the actual weight determines the shipping cost. Understanding DIM pricing is crucial for businesses to control shipping expenses, optimize packaging, and choose cost-effective shipping options. Efficient packaging and negotiating better rates with carriers can significantly reduce DIM charges.

Why is DIM Weight Important?

DIM weight is important because it helps shipping carriers optimize their cargo space and ensures fair pricing. Without considering dimensional weight, carriers might undercharge for large, lightweight packages that occupy significant space. This could lead to inefficient use of cargo space and higher operational costs. By using DIM weight, carriers encourage more efficient packaging, which can reduce fuel consumption and the number of trips required to transport goods.

What is a DIM Divisor?

The DIM Divisor is a standard number set by shipping carriers to convert the volume of a package into its dimensional weight. It represents the volume in cubic inches per pound. The DIM Divisor helps carriers standardize the DIM weight calculation, allowing for a consistent approach to billing based on the space a package occupies rather than just its actual weight.

However, the DIM divisor is not always the most critical factor in determining shipping costs, and here’s why. You might encounter a DIM divisor of 240, but the actual shipping cost could be higher if your fulfillment company doesn’t offer a fair rate. For example, if a fulfillment company uses a DIM divisor of 240 for a 12x12x12 box, resulting in a DIM weight of 7.2 lbs, the shipping cost might be $20.00. Conversely, another fulfillment company with a DIM divisor of 166 might charge $18.00 for the same box, with a DIM weight of 10.4 lbs.

All fulfillment companies are not equal; some have higher operating costs, leading to higher shipping rates. To ensure you are not overpaying, always request a rate sheet from your fulfillment company. This allows you to compare rates effectively, even if you have a higher DIM divisor.

How Can You Reduce Dimensional Weight Charges?

To reduce dimensional weight charges, businesses can take several steps:

- Optimize Packaging: Right-size your packages by using smaller boxes and eliminate unnecessary packaging materials. Ensure that the package dimensions are as compact as possible without compromising the safety of the contents.

- Invest in Compression Packaging: For items that can be compressed without damage, use vacuum-sealed bags or other compression packaging techniques to reduce the volume of the package.

- Negotiate with Carriers: Some carriers offer flexible DIM Divisors or discounts for high-volume shippers. Negotiating better terms can help reduce shipping costs or work with a 3PL that has established relationships with carriers and discounted pricing.

How is DIM Weight Calculated?

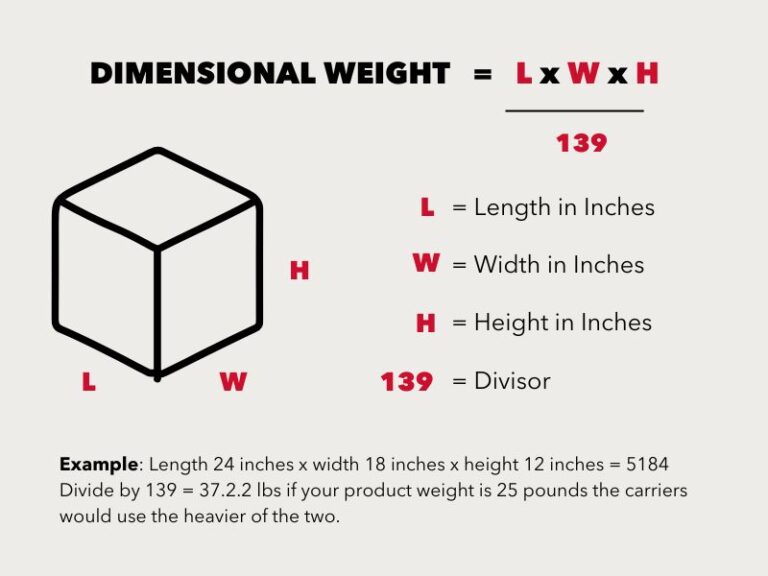

The calculation of DIM weight involves measuring the package dimensions (length, width, and height) in inches. Multiply these dimensions to get the cubic inch volume of the package. Then, divide this volume by the DIM Divisor set by the carrier. The formula is:

DIM Weight =

Length x Width x Height

DIM Divisor

For example, if a package measures 24 inches in length, 18 inches in width, and 12 inches in height, and the carrier’s DIM Divisor is 139, the calculation would be:

DIM Weight=24×18×12 ≈37.2 pounds

139

Common Mistakes in Dimensional Weight Calculation

- Incorrect Measurements: Failing to measure the package dimensions accurately can lead to incorrect DIM weight calculations. Always measure the longest points of the package.

- Using the Wrong DIM Divisor: Different carriers use different DIM Divisors. Ensure you use the correct divisor for the carrier you are shipping with.

- Ignoring Packing Materials: Not accounting for the size added by packing materials can result in underestimating the package dimensions and facing unexpected charges.

The Impact of Dimensional Weight in E-commerce

In e-commerce, where shipping costs significantly impact the bottom line, understanding and managing DIM weight is crucial. High dimensional weight can lead to increased shipping costs, which can either reduce profit margins or be passed on to customers, potentially affecting sales. By optimizing packaging and understanding DIM weight pricing, e-commerce businesses can better control shipping costs and improve customer satisfaction.

What is the International DIM Divisor?

The international DIM Divisor can vary by carrier and region, but it is often set to 139 or 166. These divisors are used for international shipments to standardize the calculation of dimensional weight. The choice of DIM Divisor affects the billable weight and, consequently, the shipping cost.

Understanding the DIM Divisor and its impact on DIM weight pricing is essential for any business involved in shipping. DIM pricing ensures that shipping costs reflect both the size and weight of a package, promoting efficient use of cargo space and fair pricing. By accurately calculating DIM weight and using the appropriate DIM Divisor, businesses can avoid unexpected shipping charges. Additionally, optimizing packaging, negotiating better rates with carriers, and being mindful of common calculation mistakes can significantly reduce shipping expenses. For e-commerce businesses ,managing DIM weight effectively can enhance profitability and improve customer satisfaction. By mastering these concepts, businesses can streamline their logistics operations, control costs, and maintain a competitive edge in the market.