Cost-effective strategies are essential for the growth and sustainability of small businesses in the ecommerce landscape. Recognizing the importance of affordability, we wanted focus on exploring various strategies and approaches that small businesses can adopt to fulfill ecommerce orders in the US without breaking the bank.

The Misconception of Multiple Warehouses

The common belief in the ecommerce industry is that having multiple warehouses is necessary for successful order fulfillment. This belief stems from the perception that having warehouses strategically located across different regions allows for faster delivery times and reduced shipping costs. This notion of multiple warehouses being essential for successful order fulfillment has been ingrained in the industry, leading many businesses to assume that expanding their warehousing footprint is the only path to achieve customer satisfaction and operational efficiency, however this is not the case and can cost business more money.

Streamlining Order Processing and Shipping with a Midwest fulfillment center

Streamlining order processing and shipping with a Midwest fulfillment center, particularly in the Chicagoland area, can offer significant advantages to businesses. Illinois, being centrally located has several sorting stations which makes it an ideal hub for efficient distribution across the country. Additionally, the Midwest’s robust transportation infrastructure and access to major highways, railroads, and airports further enhance the logistical efficiency of order fulfillment. By capitalizing on the strategic benefits of a Midwest or Illinois fulfillment center, businesses can streamline their order processing and shipping operations, resulting in improved operational efficiency and a competitive edge in the ecommerce landscape.

California Fulfillment Warehouses

California Fulfillment Warehouses

When considering warehousing options, businesses should be aware that storing products in a warehouse in California might not yield the anticipated cost savings. While the proximity to ports and the West Coast market might initially seem advantageous, it’s crucial to factor in the high costs associated with operating a warehouse in California. Real estate prices in the state, especially in prime locations, can be exorbitant, resulting in significant overhead expenses for businesses. Additionally, labor costs in California tend to be higher compared to other regions, adding to the overall operational expenses of running a warehouse.

Furthermore, logistics and transportation costs may also be impacted due to California’s congested roadways and shipping ports. These factors combined can offset any potential savings from reduced shipping distances as these costs tend to be passed on in different fulfillment fees from the fulfillment center or 3PL. Majority of your cost will be the cost to ship the package to a customer not your freight cost.

When it comes to fulfilling ecommerce orders, businesses must navigate the misconceptions and challenges associated with warehousing. While the belief in the necessity of multiple warehouses for successful order fulfillment persists, the costs and complexities involved cannot be overlooked. If you are looking to centralize your products with a reputable 3pl partner that utilizes one central location, contact us today!

Additional Helpful Resources

To further support your fulfillment strategy, explore these resources from Badger Fulfillment Group:

- What is a 3PL?: Discover how third-party logistics providers can streamline your fulfillment operations.

- Order Fulfillment Q&A: Get answers to common questions about the order fulfillment process.

- Choosing the Perfect E-Commerce Platform: A comprehensive guide to selecting the best e-commerce platform for your business.

- When to Switch 3PLs: Learn when it’s time to switch to a new 3PL provider to ensure your operations stay efficient and scalable.

- Questions on Order Fulfillment Answered: Provides concise responses to common fulfillment questions, covering inventory management, shipping, and delivery options.

- Dollars and Cents in Order Fulfillment: Explore the financial impact of efficient order fulfillment strategies.

These resources provide additional insights to help you optimize your fulfillment processes and make informed decisions as your business grows.

Why Choose Badger Fulfillment Group?

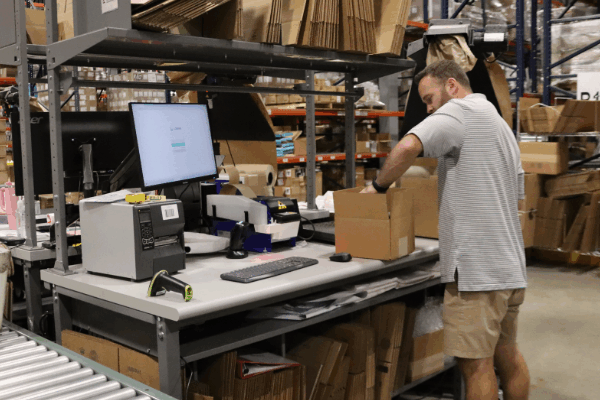

Badger Fulfillment Group can provide you with unparalleled industry expertise, integrated ecommerce solutions and the ability to pick, pack and ship your goods quickly and reliably. Our staff is located within the warehouse giving you only 1 degree of separation between you and your goods allowing for unparalleled customer service support.

California Fulfillment Warehouses

California Fulfillment Warehouses