If you are an established ecommerce merchant, researching third party logistics providers can feel confusing. One site talks about a 3PL brokerage. Another promotes a fulfillment marketplace. Another describes itself as a hybrid fulfillment partner. On the surface they all seem to promise fast shipping, great rates, and easy integrations. However, underneath those similar promises there are two very different models.

One is a 3PL brokerage that connects brands to a network of independent warehouses that it does not own or operate. The other is an asset based 3PL like Badger Fulfillment Group that runs its own facility, team, and technology from one integrated hub.

Learn how to tell which model you are speaking with, what that means for control and cost, and when a true fulfillment partner is the better fit for your brand.

Key Takeaways

What Is an Asset Based 3PL Fulfillment Partner

When a 3PL Brokerage Might Sound Tempting

What a True Fulfillment Partner Looks Like in Practice

Questions To Ask To Tell a 3PL Broker From a Fulfillment Partner

How To Decide What Your Brand Needs

Why Brands Choose Badger As Their Fulfillment Partner

What Is a 3PL Brokerage

A 3PL brokerage is a third-party logistics broker that sits between e-commerce brands and a network of independent warehouses. Instead of running a warehouse, the broker focuses on matching your inventory and order profile to one or more partner facilities.

A typical 3PL brokerage

- Does not own or operate the building where your orders are picked, packed, and shipped

- Signs a contract with your brand, then turns around and contracts with one or more warehouses on your behalf

- Focuses on sourcing capacity, coverage, and rates, not on running day to day operations

Some of these companies lean into the language of platforms or marketplaces. The underlying structure is the same. You sign with the broker. The broker passes your work to a network member. That network member touches your product.

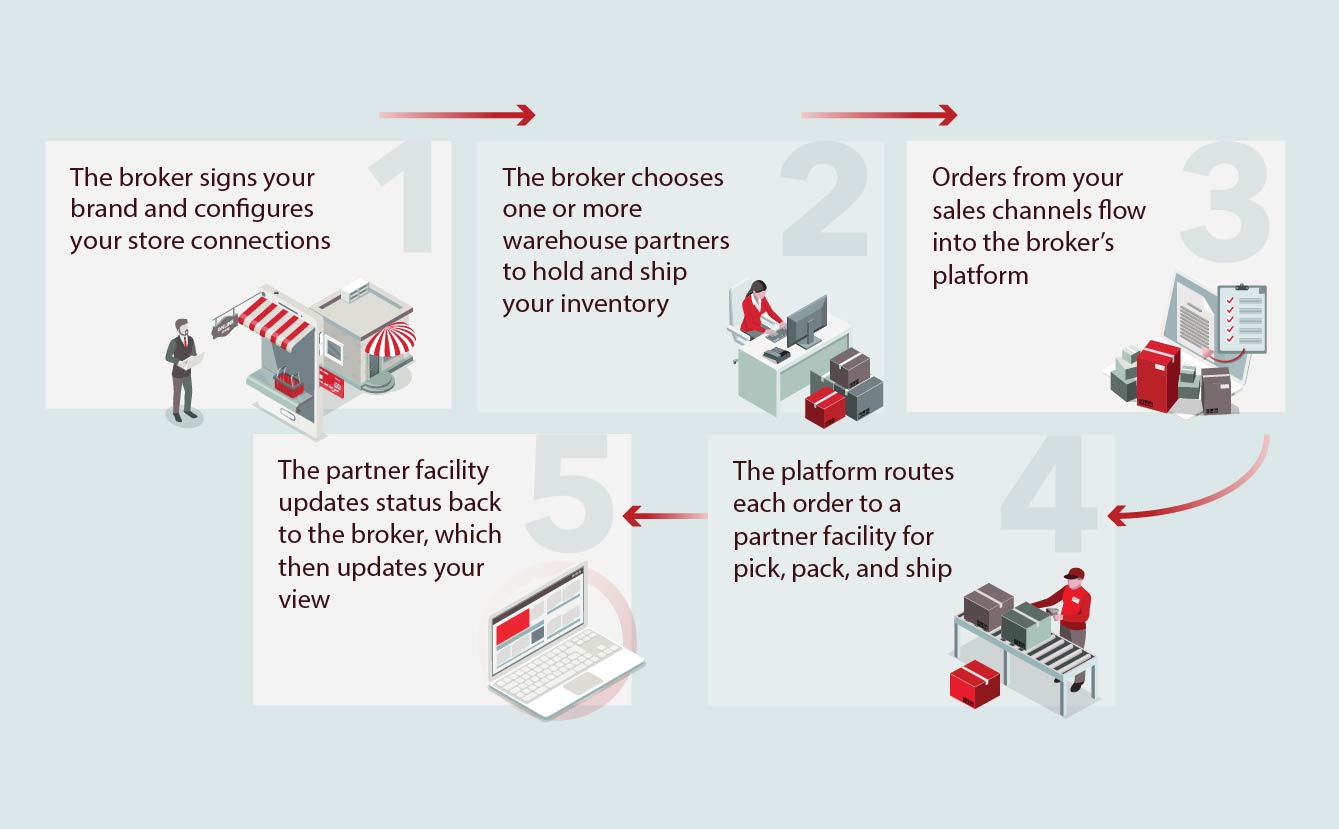

How 3PL brokers work behind the scenes

From the outside, a brokered relationship can look straightforward. Orders flow in. Shipments flow out. What happens in the middle is what matters for control and consistency.

The usual flow looks like this:

- The broker signs your brand and configures your store connections

- The broker chooses one or more warehouse partners to hold and ship your inventory

- Orders from your sales channels flow into the broker’s platform

- The platform routes each order to a partner facility for pick, pack, and ship

- The partner facility updates status back to the broker, which then updates your view

The brand’s legal relationship is usually with the brokerage, not the warehouse that is packing orders. That means any issue with inventory, packaging, or service is filtered through an extra layer of communication.

Most 3PL brokers earn revenue from a mix of:

- Margin added to storage and fulfillment fees they pay to the warehouse

- Margin added to shipping rates they negotiate with carriers

- Platform or implementation fees in some cases

This layered structure is not automatically negative, but it does make it harder to see where your money goes and who really controls your customer experience. Industry commentary regularly points to loss of direct control, hidden fees, and dependency on partner performance as core risks whenever logistics is heavily intermediated.

Common signs you are talking to a 3PL broker

You do not need to see a contract to spot a third-party logistics broker. Certain patterns show up repeatedly.

You may be dealing with a 3PL brokerage model if:

- You cannot tour their warehouse because it belongs to a partner in the network

- Your account manager cannot step out onto the floor to check an order, packaging, or inventory location

- The team struggles to explain their pick and pack process, WMS rules, or receiving steps in detail

- Service level agreements talk about overall network performance rather than one specific facility with clear cut promises

- Most of the sales pitch focuses on access to many warehouses, not on specific operational strengths or proven processes

When several of these are true, you are likely speaking with a 3PL broker rather than an asset-based fulfillment provider. Phrases like 3PL brokerage, 3PL broker, or third-party logistics broker are your hint to dig deeper into how the model actually works.

What Is an Asset Based 3PL Fulfillment Partner

An asset based 3PL owns and operates the warehouse space, equipment, and fulfillment team that handle your orders. Instead of spreading work across a large anonymous network, the provider builds deep expertise inside its own facility and keeps your brand close to the people who run your account.

You can think of 3PL brokerage vs 3PL fulfillment partner as a choice between a matchmaker and a direct relationship. Both can move inventory from point A to point B, but the experience is very different once you start growing.

Let’s look at how a 3PL brokerage compares to an asset based fulfillment partner like Badger Fulfillment Group:

Control and visibility

With a broker, control is indirect. You log into the broker’s portal and see status updates, but you have limited visibility into how work is done on the floor. Process changes require the broker to convince each warehouse partner, which takes time and may not land consistently across locations.

With a fulfillment partner, there is a direct line to the team that manages your orders. On-site account managers and operations leaders can tweak pack outs, inserts, or special handling details in close collaboration with your brand. If a particular SKU needs extra packaging or a new instruction, you speak with the people who can implement the change.

Service and support model

Broker support teams are widespread, not inside the warehouse. They may be helpful and responsive at times, but they are still one step removed from your actual inventory. When something goes wrong, they need to open tickets with a partner facility, wait for answers, and relay information back to you.

Badger takes a different approach. Dedicated support lives inside the warehouse and works side by side with the floor team. When a merchant has a question about a shipment, a specific lot, or an unscanned return, the account manager can walk to the location, inspect items, and coordinate with floor leads in real time.

Customization and special projects

For a brokered model, each custom request becomes a negotiation with every warehouse that touches your orders. Complex kitting, personalized bundles, and subscription box themes can be difficult to standardize across many independent partners.

An asset-based fulfillment partner treats customization as part of core operations. Badger handles kitting, subscription programs, and bundles from the same facility that manages standard DTC and B2B orders. That makes it easier to run campaigns like seasonal kits, gift with purchase, or multi step unboxing experiences without rebuilding your process for every new idea.

Pricing transparency

With a 3PL brokerage, there are multiple layers in the pricing structure. The warehouse charges the broker. The broker adds margin on storage, pick and pack, and shipping. The final invoice you see often blends carrier costs, warehouse costs, and broker markup in ways that are hard to untangle.

Badger has transparent pricing with clearly defined line items for storage, pick and pack, packaging materials, and postage. When volume grows, Badger offers volume discounts on warehousing to share the benefits of scale with clients.

Performance and SLAs

Brokered SLAs are only as strong as the weakest warehouse in the network. If a partner facility is short staffed or behind on receiving, your orders feel the impact even if the broker’s platform looks polished.

A fulfillment partner like Badger runs a single operational playbook with consistent expectations, including

- Same day pick, pack, and ship for ecommerce orders received before the cutoff

- A 24 hour receiving process that brings inventory into stock quickly so you can begin shipping without long delays

When a 3PL brokerage might sound tempting

At first, 3PL brokerages can look like an easy win for cost conscious brands. Common selling points include

- Low introductory rates on storage and shipping

- Fast quotes and quick onboarding timelines

- Access to a nationwide network of warehouses that promise proximity to customers

For very simple operations, this can be seen as enough, but there are hidden tradeoffs

Hidden tradeoffs

The challenges often appear as order volume, channels, and customer expectations grow. Common pain points include

- Inconsistent packaging quality between locations, which can dull your brand experience

- Limited flexibility when you want to test new pack outs, inserts, or personalization

- Slower issue resolution when a mishap or inventory discrepancy needs investigation across multiple partners

- Difficulty coordinating complex projects such as seasonal kits, gift with purchase campaigns, or detailed routing guides for retailers

- Issues with consistent and efficient processes as order volume increases especially during peak times.

- Add on costs that aren’t transparent in the initial sales process and continued rate volatility

These issues map closely to the risks shippers mention when they talk about outsourced logistics in general loss of control, hidden fees, and dependency on partner performance.

What a true fulfillment partner looks like in practice

Rather than focusing on abstract differences, it helps to look at what merchants experience day to day when they work with an asset-based partner like Badger.

One degree of separation from your inventory

Badger’s support structure is built around on site account managers who sit in the same building as the warehouse team. They can:

- Walk the floor to spot check packaging, storage locations, or a specific outbound shipment

- Pull samples and share photos or videos when you want to see how a new presentation looks in real life

- Talk directly with pickers and supervisors to fine tune instructions for fragile items, liquid products, or high value goods

That level of proximity is difficult to replicate when your main contact sits outside the warehouse and depends on a separate partner to investigate every detail.

Operational excellence you can see

Badger’s operations are designed around two main promises

- Inventory is received, inspected, counted, and stored within a 24-hour window so that stock moves quickly from dock to shelf

- Ecommerce orders received before the cutoff are picked, packed, and shipped the same day, supported by technology that gives real time visibility into orders and inventory

Because technology, receiving, and shipping are all integrated, merchants see fewer surprises and can plan marketing, launches, and promotions with greater confidence.

Support for DTC and B2B from one facility

Many brands reach a point where they are no longer purely direct to consumer. They add wholesale, retail, or marketplace channels on top of their existing ecommerce store. Badger is built for this multi-channel reality.

From the Harvard Illinois warehouse, Badger

- Ships individual parcels to consumers across the United States

- Builds pallets, follows routing guides, and supports bulk orders for retailers and marketplaces

- Handles subscriptions, kits, and special bundles alongside standard orders, so you do not have to juggle multiple providers for each channel

This single hub model helps reduce fragmentation and keeps your data and inventory more consistent.

Pricing built to help you grow

Badger’s pricing approach is designed for established brands that expect to scale. That includes

- Clear line items for warehousing, pick and pack, materials, and shipping

- Volume discounts on storage when your ecommerce sales and shipping volume increase, so your growth is rewarded

For merchants that have worked with providers where costs feel opaque or unpredictable, this transparency is often a deciding factor.

Questions to ask to tell a 3PL broker from a fulfillment partner

You do not need to guess which model a potential provider uses. A focused set of questions will usually reveal the answer.

Questions about operations

- Who employs the people picking and packing my orders?

- Where is the warehouse located, and can I tour it or meet the team?

- How do you handle receiving and what is the time table when new inventory arrives?

- Do you own and operate the facility where my inventory will live, or do you work through a network of partners?

If the answers are vague or focus on a large network without a clear primary facility, you may be speaking with a 3PL brokerage.

Questions about support

- Where does my account manager sit during a typical day

- How often will I hear from them and what is the expected response time when an issue comes up

- How do you handle peak seasons or big promotions when ticket volume increases

- Can my account manager physically inspect my inventory or orders when needed

An asset-based partner will be able to explain how on site account management works and how communication flows between support and the warehouse floor.

Questions about pricing and SLAs

- How are storage, pick and pack, and shipping charges broken out on my invoice?

- Who owns carrier relationships and negotiates rates?

- What are your order cutoffs for same day shipping and how do you enforce them inside the warehouse?

- How do you monitor and report on SLA performance?

Use the answers to place each provider on a spectrum broker, asset-based fulfillment partner, or a hybrid model that mixes both.

How to decide what your brand needs

Different stages of growth can justify different choices. The goal is not to say that a broker is always wrong, but to give you a clear framework for when an asset based 3PL becomes the smarter long-term move.

Early stage brands

If you are shipping relatively low order volumes, selling a small number of simple SKUs, and testing product market fit, a broker may feel like a reasonable short-term solution. You may value low upfront costs and rapid onboarding more than deep customization.

Signs that it is time to graduate to an asset based 3PL include:

- Order volume regularly in the hundreds or thousands per month

- Customers in multiple regions where two-day coverage matters more

- Early experiments with branded packaging, inserts, or kits that require more hands-on support

Once you reach this stage, the hidden friction of a brokered model often starts to show up in missed details and slower issue resolution.

Scaling brands with multi-channel demand

For established merchants building out DTC plus wholesale, retail, or marketplace channels, fragmentation is the main risk of a brokered model. Multiple brokered sites can create

- Different packaging standards across locations

- Inconsistent inventory visibility when stock is scattered

- Repeated onboarding efforts with each new warehouse partner

An asset based 3PL that supports DTC and B2B from one facility helps keep everything aligned. Badger’s warehousing and fulfillment services are designed to let you ship to consumers, retailers, and marketplaces without splitting your inventory across many unconnected warehouses.

Established brands considering a switch

If you already work with a 3PL and are wondering whether it is time to make a change, then look at the results you are getting.

Common signals that it may be time to switch your 3PL partner include:

- Frequent errors or short ships that are hard to trace back to a single root cause

- Slow or incomplete answers when you ask for operational details

- Difficulty launching new projects such as complex kits, subscriptions, or retailer specific requirements

- Poor visibility into true costs because invoices blend many different fees

At this point, the limitations of the wrong 3pl partner can hold back a brand that is otherwise ready to scale.

Why brands choose Badger as their fulfillment partner

Badger Fulfillment Group was built for established ecommerce brands that want fulfillment to function as a growth engine rather than a constant bottleneck. That is true across cosmetics, CBD products, lifestyle brands, and more.

Real results from brands that switched to Badger Fulfillment Group

Amazing Cosmetics spent years wrestling with fulfillment through both a previous 3PL and an in-house warehouse. They needed a partner with systems built for smaller pick and pack items and a team that could provide a close working relationship. Moving to Badger helped them step away from operational headaches and focus on product and brand again.

Aspen Clean needed a provider that could handle a significant volume of liquid products with careful handling and compliance care. What stood out to them in Badger’s approach was a clear willingness to make the partnership work for both sides, plus upfront communication about capabilities and adaptability to customized needs. Working with an onsite account manager improved both communication and logistics efficiency.

Halo Ball came to Badger after working with a previous 3PL where higher costs and limited customer service offset the benefits of a large network. They chose Badger for competitive pricing, a personal connection with the team, and proximity to their headquarters. The ability to visit the warehouse, meet with their account manager, and walk through the software in person gave them confidence that their fulfillment partner was invested in their growth.

Lifestyle brands like Wilde House Paper value fulfillment that feels as intentional as their products. Badger’s combination of hands-on collaboration, scalable systems, and transparent pricing helped Wilde House Paper grow direct to consumer sales while keeping a very specific packaging and customer experience intact.

These stories all point to the same pattern, the need of an asset-based partner with in-warehouse support to improve accuracy, communication, and their customer experience.

A true fulfillment partner should feel like an extension of your team, not another layer you have to manage. If you are ready for a more direct relationship with your 3PL, Badger Fulfillment Group is ready to talk through where you are today and what is possible from here.